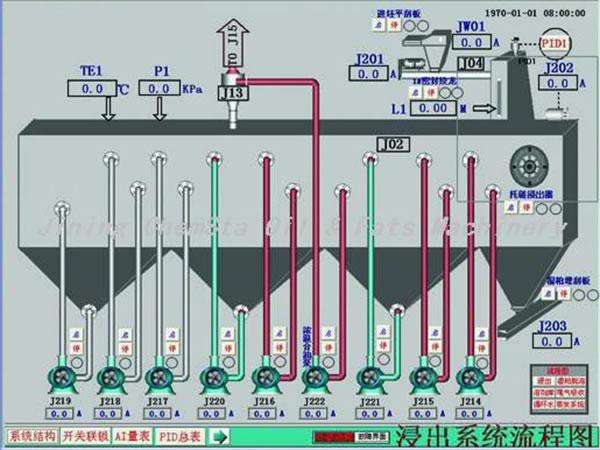

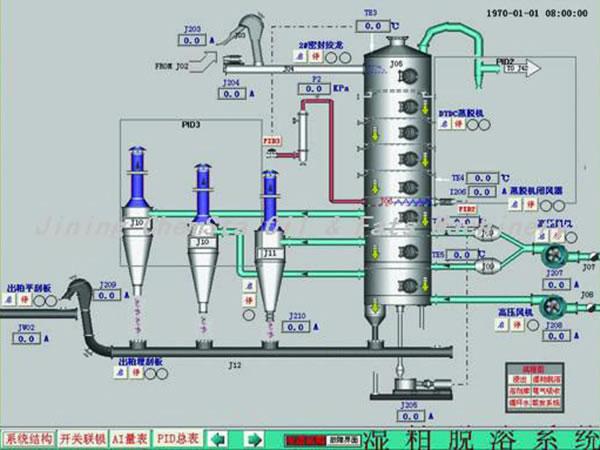

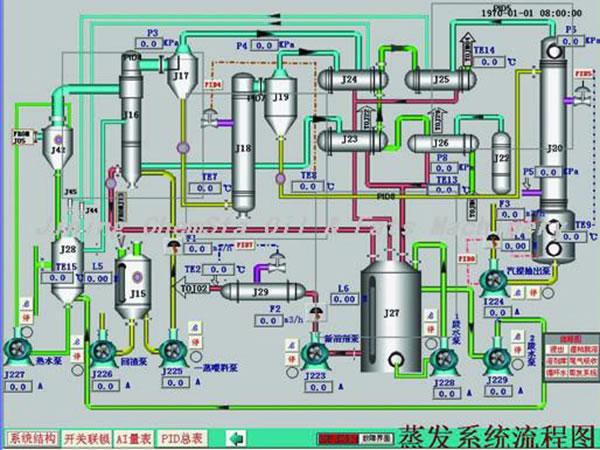

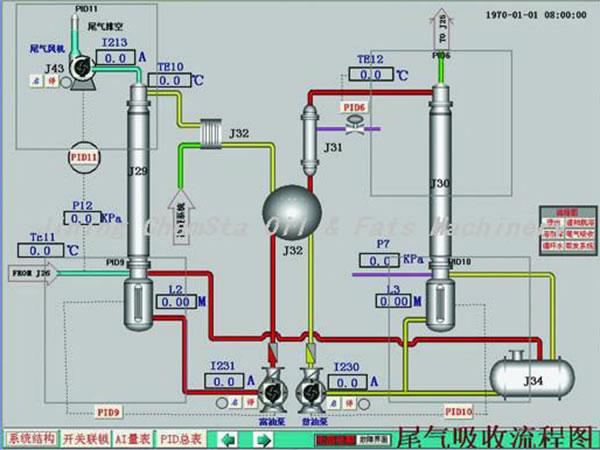

Automatic Control System

In our production lines, we make use of Siemens PLC control system, which is one of mainstream automatic control systems in today’s industry. The efficient, stable and advanced DCS control system consists of operation station, control station and communication network. We utilize high-speed and large-capacity S7-400 series PLC at the control system, large-screen LCD at the operation station, WINCC 7.0 industrial control software and PROFIBUS filed bus network.

Features

1. Every stage of the whole production line is dynamically and clearly displayed on the computer screen at the operation station.

2. The control system enables users to start or stop motors and electrical equipment using the computer.

3. Acquisition and control of parameters are all accomplished by the programme written in the control station. In this way, operation station only undertakes things such as operation, parameter display, data record and data storage.

4. For important parameters, the control system is able to ensure automatic control, data storage and alarm when values of these parameters exceed preset limit values.

5. It is very convenient to print relevant reports.

6.The control system is characterized by high reliability, stability, great resistance to disturbance

7. User-friendly human machine interface contributes to great convenience.

8. PROFIBUS field bus network ensures rapid and reliable communication.

9. Open ODBC and OLE standard interfaces are also equipped in the control system, which facilities communication with the host computer and other control systems.

10. The control system also features remote monitor and fault diagnosis.