Natural Product Extraction Project

Our company is specialized in designing production processes for natural pigments, natural essential oils, natural oleoresins, natural nutritive and medical extracts. Furthermore, we are also capable of developing, manufacturing, installing and debugging relevant machines used for extraction of natural pigments.

Raw Materials: chili particles, chrysanthem particles, etc

Products: paprika red pigment, capsaicin, phytoxanthin

Applications: food, medicines, seasonings, cosmetics, and health care products.

Production Process

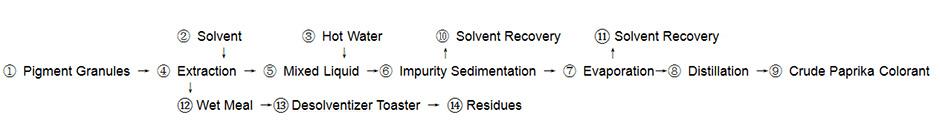

1. Extraction

One. ① Pigment Granules → ④ Extraction → ⑤ Mixed Liquid →⑥ Impurity Sedimentation → ⑦ Evaporation→⑧ Distillation →⑨ Crude Paprika Colorant

Two. ① Pigment Granules → ④ Extraction → ⑫ Wet Meal →⑬ Desolventizer Toaster → ⑭ Residues

Major Devices

Elevator and conveyor, extractor, evapo-separated machine, evaporator, distillation still, cooler, solvent circulatory system, electrical control equipment and other auxiliary devices.

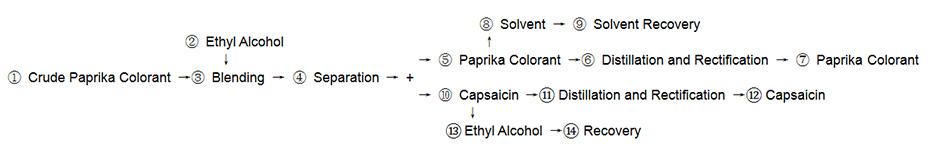

One. ① Crude Paprika Colorant →③ Blending → ④ Separation → ⑤ Paprika Colorant →⑥ Distillation and Rectification → ⑦ Paprika Colorant

Two. ① Crude Paprika Colorant →③ Blending → ④ Separation → ⑩ Capsaicin →⑪ Distillation and Rectification →⑫ Capsaicin

Major Devices

Blender, reactor, separator, rectifying column, solvent recovery system, cooling system, electrical control equipment and other auxiliary devices.

Production Capacity:

30t/d-100t/d pigment