Vegetable Oil Processing ProjectChemSta has been dedicated in designing and manufacturing devices used in oil production lines and vegetable protein production lines for more than 30 years. Up to now, there are about 200 successful engineering cases at home and abroad.

-

- Oilseed Pretreatment Line We are always designing and manufacturing vegetable oil pre-treatment and pressing line based on characteristics of different vegetable oils as well as customers’ requirements.

-

- Oilseed Pressing Line Major Devices: automatic control box for material level, magnetic separator for iron removal, flaking mill, hydraulic driving station and conveyor.

-

- Vegetable Oil Extraction Line Major Devices: extractor, desolventizer-toaster with integrated dryer-cooler, negative pressure evaporator, horizontal stainless pipe bundle condenser, filtering system for removing meal foam from miscella...

-

- Vegetable Oil Refining Line Our vegetable oils and fats refining line is suitable for refining of various oils including soybean oil, rapeseed oil, cottonseed oil, peanut oil, sunflower seed oil, corn germ oil and rice bran oil.

-

- Cottonseed Miscella Refining Line in Extraction Workshop Filter, evaporator, acid weighing pump, alkali weighing pump, acid reactor,alkali reactor,disc centrifuge, heat exchanger, desolventizing device, vacuum system, holding tank, electrical control equipment.

Vegetable Protein Processing LineWe provide professional and systematic solutions for production of vegetable oils and vegetable proteins.

-

- Soybean Meal Production Line We provide various soybean intensive processing lines, one of which is suitable for production of low temperature soybean meal.

-

-

- Soy Protein Concentrate Production Line In our production line, edible alcohol is used to extract and separate water-soluble components (mainly soluble sugars) from low-temperature soybean flakes.

-

-

- Soy Protein Isolate Production Line Severing as a kind of food additive, soybean protein isolate is able to efficiently improve the protein content of the food, thus improving food functional performance.

-

-

- Cottonseed Protein Production Line Cottonseed go through delinting, husking, low temperature softening, flaking, conditioning, leaching, degreasing , drying, toxic substance (gossypol) removal to produce cottonseed protein, which contains about 90 percent globin.

-

-

- Full Fat Soybean Powder Production Line Rising conveyor, magnetic separator, scale, huller, kernel husk separator, horizontal softening machine, flaking mill, dryer, air net for dust removal, electric control equipment and other auxiliary devices.

-

-

- Natural Product Extraction ProjectFurthermore, we are also capable of developing, manufacturing, installing and debugging relevant machines used for extraction of natural pigments.

- Livestock and Poultry Carcass Disposal EquipmentMeat meal is a kind of environmental friendly feed additive which is high in protein ,while grease can be used as industrial oil or biodiesel.

- Biodiesel Production Turn-key ProjectOur biodiesel plant enables users to produce biodiesel using various oils, which contain free fatty acid in any quantity, even 100 percent.

Pressure Vessel, Dryer Our company is committed to R&D, design and manufacture of various ASME pressure vessels, high pressure heat exchangers and rotary dryers.

-

- Biomass DryerCompact layout, simple structure, high heat change efficiency, low heat consumption, energy conservation, a wide range of applications, large capacity, large evaporation capacity, thorough blending of material in the rotary drum, no residue

-

- High Pressure Heat ExchangerComplied with ASME standards,the heater is designed to heat natural gas using water vapor. Then the natural gas can enter sequential combustor directly.

-

- Three Phase SeparatorDevice Name: Three-Phase Horizontal Separator

Medium: acid medium

Design Temperature :-0.489361702℃

Dimensions: Φ1,800*8,200*20/Φ1,400*6,000*60 (6 sets in total)

-

- ASME Pressure VesselVessel Name: Filter

Medium: lubricating oil

Design Temperature :125℃

Dimensions: Φ900*1,200*10/Φ1,000*1,300*10

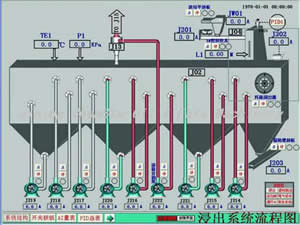

- Automatic Control SystemIn our production lines, we make use of Siemens PLC control system, which is one of mainstream automatic control systems in today’s industry.