Biomass Dryer

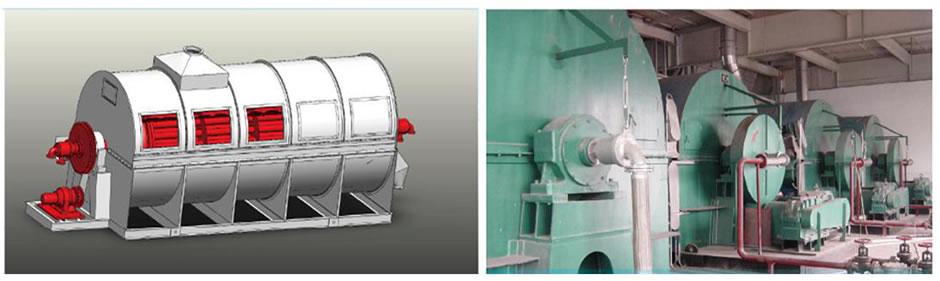

Rotary Tube Bundle Dryer

Features

Compact layout, simple structure, high heat change efficiency, low heat consumption, energy conservation, a wide range of applications, large capacity, large evaporation capacity, thorough blending of material in the rotary drum, no residue

Applications

The dryer is extensively applied to dry loose materials in chemical industry, light industry and food industry, grain industry and fodder industry.

Heat Source

Low or medium pressure steam

Rotary Dryer with Large Drum

Features

1. The dryer features low working temperature and high safety factor because it is able to efficiently prevent combustion of materials dried.

2. Combination of hot wind and steam contributes to large evaporation capacity.

3. Hot wind, inclined drum and big spiral installed inside of the drum together make the materials flow flexibly in the drum.

Applications

1. The dryer is suitable for drying of biofuels such as fibrous barks, saw powder, bamboo chippings, wooden chippings, wood shavings, barley straws, oat straws, wheat straws, rye straws, straws, sorghum straws, maize straws, bean stalks, animal waste.

2. In chemical industry, mining industry and metallurgical industry, our dryer can be used to dry large particles including mill tailings, blast furnace slags, coals, metal powder and phosphatic fertilizers, etc.

3. It is also applied for drying of stillage, embryos, starches, soybeans, bean dregs in grain industry.

Heat Source

Hot wind/flue gas/low or medium pressure steam

Horizontal Disc Dryer

Features

Indirect drying, small oxygen concentration, small amount of exhaust gas, large evaporation area, small occupied area, low rotating speed, minimum wear and breakage

Applications

Environmental Protection Industry: drying of sludge(moisture content <85%)

Food Industry: drying of plant protein powder, animal protein powder

Heat Source

Low or medium pressure steam/ conduction oil